Accurate depth measurement plays a pivotal role in various industries, enabling efficient resource management, safety, and decision-making. Ultrasonic level sensor has emerged as a powerful tool for uncovering the true depth of substances. In this article, we delve into the capabilities and advantages of ultrasonic level sensor, showcasing their ability to go beyond the surface and provide accurate depth measurements.

Understanding Ultrasonic Level Sensors

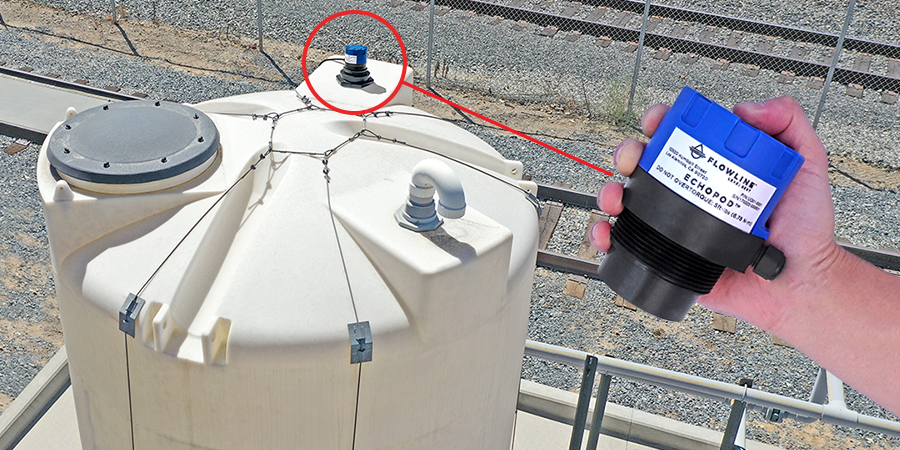

Ultrasonic level sensors utilize advanced technology to measure depth accurately. By emitting high-frequency sound waves and analyzing the return signals, these sensors calculate the distance to the substance being measured. This enables precise depth measurement across a wide range of applications and industries.

Going Beyond the Surface

1. Depth Measurement Capabilities

Ultrasonic level sensors excel in accurately measuring depth. Industries such as oil and gas, mining, and environmental monitoring heavily rely on precise depth information. Whether it’s monitoring the depth of fluid levels in tanks or measuring the depth of sludge in reservoirs, ultrasonic sensors provide crucial data for operational efficiency, safety, and compliance.

2. Non-Contact Depth Sensing

One of the significant advantages of ultrasonic level sensors is their non-contact depth sensing capability. Unlike traditional contact-based methods, ultrasonic sensors measure depth without physical contact with the substance being measured. This non-contact approach ensures the integrity of the material and eliminates the risk of contamination or damage. It also allows for versatile applications in challenging environments.

3. Applications in Challenging Environments

Ultrasonic level sensors thrive in challenging environments, making them ideal for applications such as underwater depth measurement or monitoring in harsh weather conditions. Their ability to operate reliably in extreme environments sets them apart from other depth measurement technologies. Real-world case studies in industries like marine exploration and offshore operations demonstrate the successful use of ultrasonic sensors in demanding environments.

Unveiling the Advantages

1. Accuracy and Precision

Ultrasonic level sensors offer high accuracy and precision in depth measurement. By utilizing advanced algorithms and signal processing techniques, these sensors deliver reliable and repeatable measurements. Accurate depth information is crucial for optimizing processes, preventing overflows, and ensuring optimal resource management. Industries such as wastewater treatment, chemical processing, and agriculture benefit significantly from the precise depth measurements provided by ultrasonic sensors.

2. Versatility and Adaptability

Ultrasonic level sensors are highly versatile, capable of measuring depth across different substances, including liquids, solids, and sludge. This versatility makes them suitable for a wide range of applications across industries. Additionally, ultrasonic sensors can adapt to varying tank sizes, shapes, and materials. They can be easily integrated into existing systems, making them a flexible and cost-effective choice for depth measurement needs.

3. Real-Time Monitoring and Control

Ultrasonic level sensors enable real-time depth monitoring and control. By providing continuous and accurate depth data, these sensors support efficient decision-making and process optimization. Real-time monitoring helps identify trends, detect anomalies, and enable proactive maintenance, leading to enhanced productivity and cost savings. Industries can leverage this feature for inventory management, water resource monitoring, and other critical operations.

4. Integration with IoT and Automation

Ultrasonic level sensor can be seamlessly integrated with IoT platforms and automation systems. This integration allows for remote monitoring, data analytics, and automated control. By harnessing the power of connected technologies, industries can achieve higher levels of efficiency, reduce human error, and optimize resource allocation. Ultrasonic sensors play a vital role in the digital transformation of industries, paving the way for smarter, data-driven decision-making.

Case Studies and Real-World Applications

To illustrate the advantages of ultrasonic level sensors, let’s explore a few real-world case studies:

1. Case Study 1: Enhancing Oil and Gas Operations with Accurate Depth Measurement

– Discuss how an oil and gas company optimized their drilling operations by using ultrasonic level sensors to accurately measure wellbore depth.

– Highlight the impact of precise depth information on well integrity, reservoir management, and production optimization.

2. Case Study 2: Optimizing Mining Processes with Real-Time Depth Monitoring

– Showcase how a mining company improved their extraction processes by implementing ultrasonic level sensors for real-time depth monitoring in tailings ponds.

– Discuss the benefits of accurate depth measurements in tailings management, environmental compliance, and water conservation.

3. Case Study 3: Environmental Monitoring and Water Resource Management

– Explore how ultrasonic level sensors were deployed for real-time depth measurement in river systems to monitor water levels, flood risk, and water resource availability.

– Emphasize the importance of accurate depth data in environmental planning, flood prevention, and sustainable water management.

Overcoming Challenges and Considerations

While ultrasonic level sensors offer numerous advantages, it’s essential to address potential challenges and considerations. Factors such as foam, turbulence, or varying substance densities can impact the accuracy of ultrasonic sensors. However, with proper installation techniques, foam suppression methods, and calibration, these challenges can be effectively mitigated. Additionally, alternative technologies like radar sensors can be considered for applications where ultrasonic sensors face limitations.

Conclusion

Ultrasonic level sensors have revolutionized depth measurement across industries, enabling accurate and reliable data acquisition. By going beyond the surface, these sensors provide invaluable insights for optimizing processes, enhancing safety, and ensuring efficient resource management. The accuracy, versatility, real-time monitoring, and integration capabilities of ultrasonic level sensors make them a valuable tool in the pursuit of operational excellence. As industries continue to evolve, ultrasonic sensor technology will play a pivotal role in unveiling the depth and driving innovation across various sectors.