Probe card design is a critical element in the semiconductor industry, as it plays a pivotal role in ensuring the quality and performance of integrated circuits (ICs). In California, a hub for technological innovation, the art of probe card design has reached new heights, revolutionizing the way we test and manufacture these intricate components. We will delve into the world of probe card design, exploring its nuances, techniques, and advancements in the heart of Silicon Valley.

The Basics of Probe Card Design:

- Understanding The Core Principles

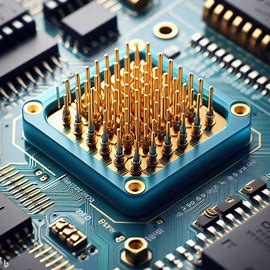

Before diving into the advanced aspects of Probe Card Design, it’s essential to grasp the fundamentals. Probe cards are used to establish electrical contact between the tester and the IC. They consist of a variety of components, including needles, ceramic substrates, and interconnectors, all meticulously designed to ensure precise measurements.

- Material Selection

California’s probe card designers pay meticulous attention to material selection. They opt for materials that offer the necessary mechanical and electrical properties, such as tungsten, beryllium copper, and specialized ceramics, to meet the exacting standards of the semiconductor industry.

Advanced Techniques:

- Multi-DUT Design

In California’s fast-paced semiconductor industry, the demand for high throughput testing is ever-increasing. To meet this demand, probes and card designers employ innovative techniques like multi-DUT (Device Under Test) design. This approach allows for simultaneous testing of multiple ICs, improving efficiency and reducing testing time.

- Fine-Pitch Probing

As semiconductor technology continues to advance, ICs are becoming smaller and more densely packed. To accommodate this trend, probe card designers in California have perfected the art of fine-pitch probing. These designs ensure that even the tiniest contact points on modern ICs can be accurately tested.

Customization and Flexibility:

- Custom Probe Card Designs

One of the key advantages of probe card design in California is the ability to create highly customized solutions. Manufacturers can work closely with probes and card designers to develop cards tailored to their specific testing requirements, ensuring optimal performance and accuracy.

- Modular Probe Card Systems

Flexibility is paramount in semiconductor testing, and California’s probe card designers understand this well. They often employ modular probe card systems that can be easily adapted to different testing needs, making them cost-effective and versatile solutions for a wide range of applications.

Cutting-Edge Advancements:

- MEMS Probe Cards

Micro-Electro-Mechanical Systems (MEMS) technology has made a significant impact on probe card design in California. MEMS probe cards are highly precise and can achieve incredibly small contact pitches. They are essential for testing the most advanced ICs, ensuring accuracy and reliability in the production process.

- Advanced Thermal Management

ICs generate heat during testing, and excessive heat can affect the accuracy of measurements. To combat this, California’s probe card designers have developed advanced thermal management solutions. These innovations ensure that probe cards maintain consistent performance even in the face of thermal challenges.

The Future of Probe Card Design:

- Artificial Intelligence and Machine Learning

California is a hotbed for cutting-edge technologies, and probe card design is no exception. AI and machine learning are being integrated into the design process, enabling more intelligent and predictive designs. These technologies help identify potential issues and optimize probe card designs for maximum performance.

- Quantum Computing Probe Cards

As the field of quantum computing continues to advance Probe Card Designers in California are already exploring the creation of specialized probe cards for this emerging technology. These cards will play a crucial role in testing and quality assurance for quantum processors.

Challenges and Innovations:

- Signal Integrity Challenges

As ICs become more complex, signal integrity is a growing concern. California’s probe card designers are continually innovating to maintain signal integrity in high-speed and high-frequency applications. They are developing solutions that mitigate signal loss and maintain measurement accuracy.

- Reducing Contact Damage

Contact damage can occur during the probing process, affecting the longevity and performance of the probe card. California’s designers are focused on minimizing contact damage through innovative materials and advanced contact management techniques.

Conclusion:

The Golden State, known for its technological prowess, stands at the forefront of probe card design. With a deep understanding of the fundamentals, a commitment to innovation, and a dedication to meeting the ever-evolving demands of the semiconductor industry, California’s probe card designers have achieved remarkable success. Their contributions not only ensure the quality of integrated circuits but also drive the advancement of technology as a whole.

California’s probe card design community continues to push the boundaries, embracing the latest technologies and materials to create the next generation of probe cards. The industry’s relentless pursuit of precision, customization, and reliability positions it as an essential cog in the wheel of technological advancement. In the dynamic landscape of semiconductor testing, the future of probe card design in California is poised to be brighter and more innovative than ever.