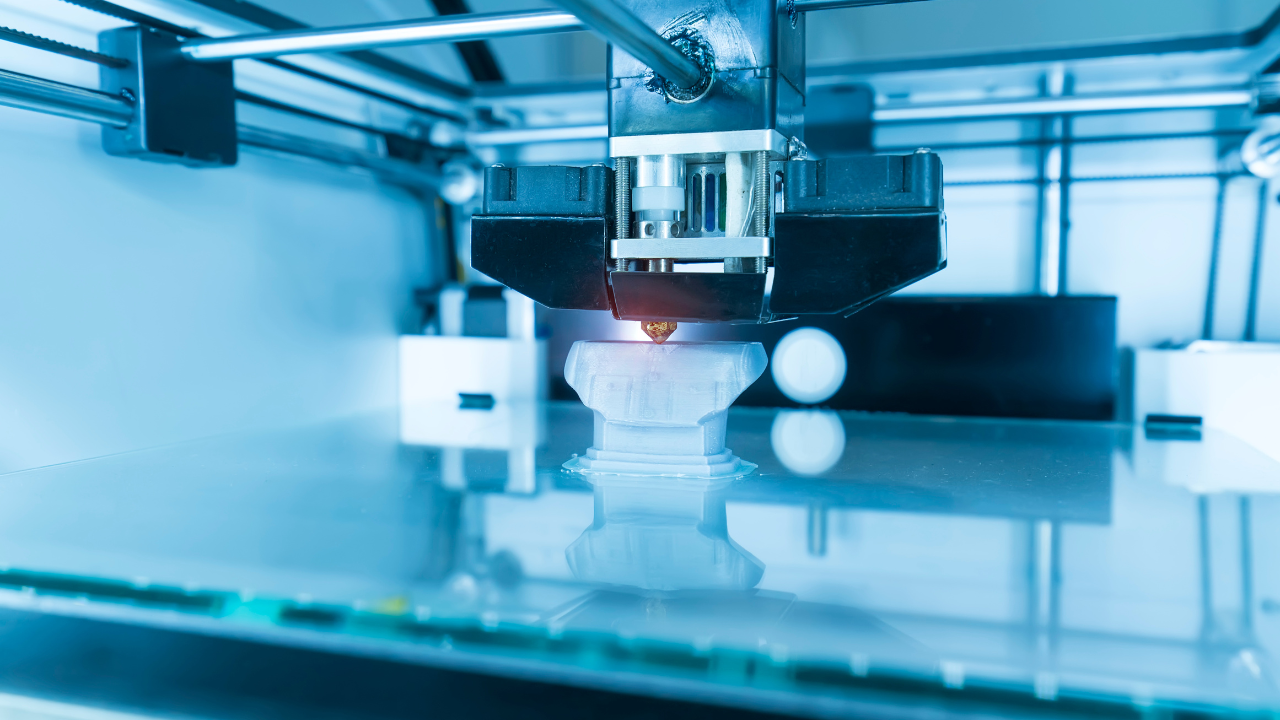

In recent years, Singapore has made remarkable strides in the field of 3D printing services, contributing to the global wave of technological innovation. This dynamic city-state has embraced the potential of 3D printing, revolutionizing various industries and enabling creative solutions to complex challenges. In this article, we will delve into the transformative impact of 3D printing services in Singapore and explore the key sectors that have embraced this technology.

The Rise of 3D Printing in Singapore

Singapore, known for its strong focus on innovation and technology, has witnessed the rapid growth of 3D printing services. With a well-established manufacturing and technology ecosystem, the country has set its sights on becoming a hub for 3D printing in the Asia-Pacific region. This growth can be attributed to various factors, including government support, the presence of leading 3D printing companies, and the city’s commitment to fostering innovation.

Government Support and Investment

The Singaporean government has been instrumental in nurturing the 3D printing industry. Through initiatives like the National Additive Manufacturing Innovation Cluster (NAMIC) and grants for research and development, it has actively promoted 3D printing technologies. These investments have not only boosted the development of 3D printing capabilities but have also encouraged partnerships between research institutions and industry players.

Diverse Applications

3D printing has permeated various sectors in Singapore, transforming the way things are designed, manufactured, and consumed. Here are some key areas where 3D printing is making significant strides:

- Healthcare: Singapore’s medical industry has benefited immensely from 3D printing. Surgeons now use 3D-printed anatomical models for pre-surgical planning, which enhances the precision and safety of complex surgeries. Customized orthopedic implants and prosthetics are also being produced, providing patients with tailored solutions.

- Aerospace: The aerospace industry relies on precision and lightweight components. 3D printing has enabled the production of intricate and high-performance parts, reducing weight and fuel consumption in aircraft. Singapore is home to aerospace giants like Rolls-Royce, which utilize 3D printing for engine components.

- Architecture and Construction: In the realm of architecture, 3D printing is pushing boundaries by creating intricate, cost-effective designs. Several construction companies in Singapore are exploring 3D printing for building structures, offering a more sustainable and efficient construction process.

- Manufacturing and Prototyping: Singapore-based companies are increasingly turning to 3D printing for rapid prototyping and small-batch manufacturing. This enables them to reduce lead times and costs while improving product quality.

Challenges and Future Outlook

While the 3D printing industry in Singapore has made significant progress, it also faces some challenges. These include the need for skilled labor, regulatory hurdles, and the cost of 3D printing equipment. However, these challenges are being actively addressed as the industry continues to grow.

Looking ahead, the future of 3D printing services in Singapore appears promising. The technology is anticipated to play an even more significant role in various sectors. As the industry matures, we can expect further innovation and specialization, leading to new opportunities and applications.

Conclusion

Singapore is embracing 3D printing services as a powerful tool for innovation and transformation. The city-state’s commitment to supporting the industry through investment and collaboration, coupled with its strong focus on research and development, has positioned it as a global leader in 3D printing technology. As the 3D printing ecosystem continues to evolve, Singapore is poised to revolutionize the future across a wide range of sectors, making it a key player in the global 3D printing revolution.