Are you ready for an exciting adventure into the world of sandwich mounts? If you’re an adult looking to explore a fascinating subject that has significant applications in various industries, then this journey is for you. Sandwich mounts may not sound like the most thrilling topic, but trust me, there’s so much more to them than meets the eye. In this blog post, we’ll dive deep into the world of sandwich mounts, understanding what they are, their significance, and why they are appealing to adults like us.

Understanding Sandwich Mounts

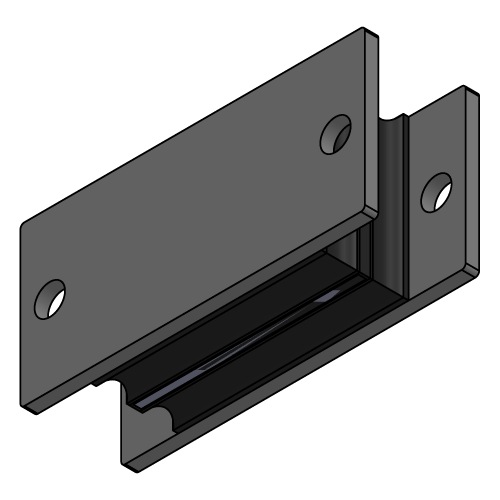

Let’s start with the basics: what exactly are sandwich mounts? Imagine you have a delicious sandwich. It consists of multiple layers of bread, toppings, and fillings. Now, instead of thinking about food, replace the bread with layers of rubber, metal, or other resilient materials. Voila! You have a sandwich mount.

Sandwich mounts are designed to provide mechanical isolation and dampen vibrations in various applications. They act as a buffer between two surfaces, absorbing shocks, reducing noise, and isolating vibrations. By doing so, they help protect sensitive equipment, enhance performance, and improve overall comfort.

In industries such as automotive, aerospace, and electronics, sandwich mounts play a crucial role in ensuring optimal functionality. For example, in the automotive sector, sandwich mounts are used to isolate vibrations from the engine, reducing noise and enhancing the driving experience. In the aerospace industry, sandwich mounts help protect delicate instruments from excessive vibrations during flights.

Types of Sandwich Mounts

Now that we have a basic understanding of sandwich mount, let’s explore the different types commonly used in industries. There are various types of mounts available, each with its unique features and applications.

1. Rubber Sandwich Mounts:

These mounts consist of rubber layers sandwiched between metal plates. They offer excellent vibration isolation and shock absorption properties, making them ideal for applications such as engine mounts, HVAC systems, and machinery.

2. Spring Sandwich Mounts:

These mounts utilize metal springs to provide excellent vibration isolation and shock absorption. They are often used in heavy-duty applications like industrial machinery, generators, and vehicles.

3. Air Spring Sandwich Mounts:

These mounts use compressed air to provide cushioning and isolation. They are commonly used in the transportation industry, such as in trucks, buses, and trains, to minimize vibrations and enhance passenger comfort.

4. Elastomeric Sandwich Mounts:

These mounts use specialized elastomeric materials to provide a balance between stiffness and flexibility. They are often used in applications where a combination of vibration isolation and stability is required, such as in precision equipment and medical devices.

Choosing the Right Sandwich Mount

Now that we know the different types of sandwich mounts, how do we choose the right one for our specific needs or applications? There are a few key factors to consider:

1. Load Capacity:

Determine the weight and load requirements of your application. Ensure that the sandwich mount you choose can handle the specified load without compromising its performance.

2. Size:

Consider the size and dimensions of the mount. It should fit properly and provide adequate support for the equipment or machinery.

3. Material Compatibility:

Pay attention to the compatibility of the mount’s materials with the surrounding environment. Factors such as temperature, chemicals, and exposure to UV radiation can affect the performance and lifespan of the mount.

4. Environmental Factors:

Evaluate the operating conditions, including temperature variations, moisture levels, and exposure to vibrations or shocks. Choose a mount that can withstand these conditions without deteriorating.

To make an informed decision, it’s always a good idea to consult with experts or suppliers who can provide guidance based on your specific requirements.

Installation and Maintenance

Once you have chosen the right sandwich mount, proper installation and maintenance are crucial to ensure optimal performance. Here are some steps to follow:

1. Installation:

Start by cleaning the surfaces where the sandwich mount will be placed. Ensure that they are free from dirt, grease, or any other debris that can affect the adhesion. Follow the manufacturer’s instructions for proper installation, including the torque specifications for any bolts or fasteners.

2. Maintenance:

Regularly inspect the sandwich mounts for signs of wear, damage, or degradation. Check for loose bolts or fasteners and tighten them if necessary. If any mount shows signs of deterioration, replace it promptly to avoid compromising its effectiveness.

3. Troubleshooting:

Sometimes, issues may arise during installation or usage. If you experience excessive vibrations, noise, or reduced performance, check if the sandwich mount is properly installed and functioning as expected. If problems persist, consult with experts to identify the root cause and find a solution.

Exploring Applications

Now that we have delved into the technical aspects of sandwich mounts, let’s explore the exciting applications where they are widely used.

1. Automotive:

In the automotive industry, sandwich mounts are utilized in engine mounts, suspension systems, and exhaust hangers. They help minimize vibrations, reduce noise, and enhance overall comfort for both drivers and passengers.

2. Aerospace:

Sandwich mounts play a vital role in aerospace applications, including avionics, aircraft landing gears, and cabin interiors. They provide isolation from vibrations and shocks, ensuring the safety and functionality of critical equipment.

3. Electronics:

In the electronics industry, sandwich mounts are used in computer servers, electronic enclosures, and sensitive instruments. They help protect delicate components from vibrations, shocks, and external disturbances.

Exploring these applications not only gives us a deeper appreciation for the effectiveness of sandwich mounts but also opens up potential career opportunities or business ideas. As we become more knowledgeable about this subject, we can explore avenues such as consulting, manufacturing, or even developing innovative sandwich mount solutions.

Conclusion:

In conclusion, our journey into the world of sandwich mounts has been an exciting and eye-opening experience. We have learned about the different types of sandwich mounts, how to choose the right one, and the importance of proper installation and maintenance. We have also explored various industries where sandwich mounts are widely used, witnessing their significant impact on performance, comfort, and safety.

As adults, it’s important to continue exploring and learning about diverse subjects, even those that may seem mundane at first glance. The world of sandwich mounts may not be the most glamorous, but its practical applications and potential for innovation make it an intriguing field worth exploring.

So, I encourage you to delve deeper into this subject, engage with experts, and consider implementing sandwich mounts in your own lives or professions. Who knows, you might just discover a whole new world of opportunities and possibilities. Learn>